Plastic Testing Machines

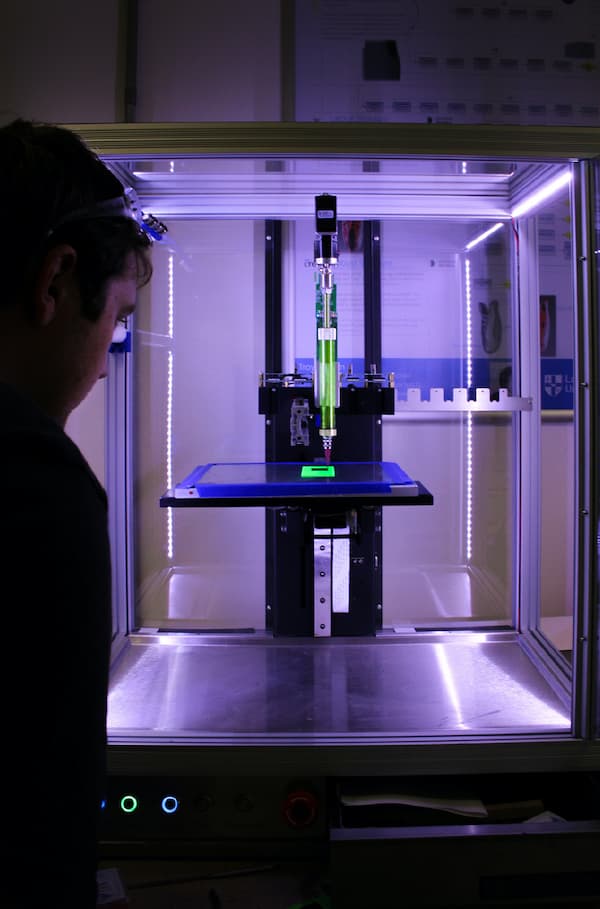

Testometric supply a comprehensive range of test systems that are dedicated to Plastic testing. They include specialised test fixtures and software for evaluating tensile, flexural, tear, shear, compression, puncture and adhesion characteristics. The systems have been specifically developed to comply with the relevant international standards.

Although plastics have only been used for approximately 100 years they have become an integral part of day-to-day life. They are used in virtually all industries and applications, including packaging, healthcare, construction, textiles and consumer goods.

There are six major polymer types that currently account for approximately 70% of global production (PET, HDPE, PVC, LDPE, PP and PS.) These are generally referred to as commodity plastics as they can be produced in high volume, at low cost and exceptional material properties are not required.

Some applications require increased mechanical properties and are defined as, “engineering plastics,” or, “high-performance plastics.” (ABS, HIPS, PEEK, PTFE etc.) These materials are generally more robust and require higher capacity testing than their “commodity plastics” counterparts.

The determination of mechanical properties is of paramount importance in the design, processing and use of polymer material. The Testometric Company Ltd. has been involved in the supply of universal testing machines to the plastics industry since its inception in 1970. The Testometric range of machines can be used to determine a large scope of mechanical properties including tensile, compression, flexural, shear, adhesion and more.

Typical adhesion test standards include:-

Our machines can also support the following plastic testing standards as well:

D1367, D3433, C273, C307, C633, BS5980.

- ASTM D638: Standard for Tensile Plastic Testing

- ISO 527 – Tensile testing of plastics, similar to ASTM D638 but used internationally.

- ASTM D790 – Flexural properties of unreinforced and reinforced plastics.

- ISO 178 – Determination of flexural properties of plastics.

- ASTM D412 – Tensile testing of rubber and elastomers.

- ASTM D695 – Compressive properties of plastics.

- ISO 604 – Compressive properties of plastics.

- ASTM D903 – Peel or stripping strength of adhesive bonds.

- BS 2782 – Methods of testing plastics.

These are just a few of the many standards we support. Our high-precision plastic testing machines are engineered to meet the rigorous requirements of these standards, ensuring accurate and reliable test results for a wide range of materials. If you have specific testing needs, we can tailor our equipment to comply with additional industry or client-specific standards.

Take a look at the most common products used by this industry:

-

TE3542 - Clip-on Extensometer, 5mm to 10mm Range

Quick View -

10X1000A3 - Clip On Extensometer

Quick View -

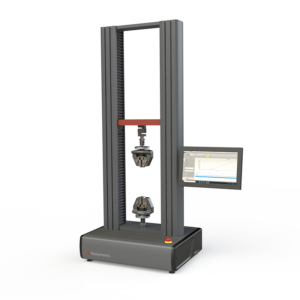

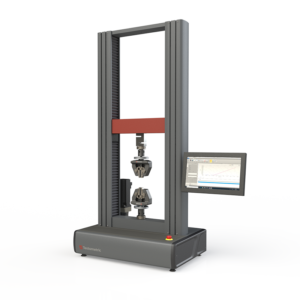

X350 - Machine

Quick View -

X500 - Machine

Quick View -

CPS400 - 400mm square compression platens. Maximum capacity 25kN to 300kN.

Quick View -

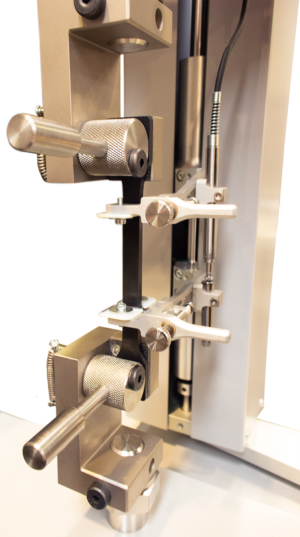

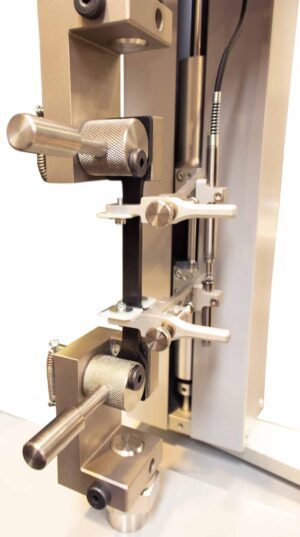

DER1 - Double eccentric roller grips. Size 1.

Quick View -

FS - Friction Slide

Quick View -

DE-A3 - Long Travel Extensometer for rubber and other elastomers, with range of 850mm by 0.01mm.

Quick View -

PPTG - Pipe Tensile Grips, 25mm

Quick View

Plastic Testing FAQs

What is ISO 527?

ISO 527 is an international standard for determining the tensile properties of plastics, similar to ASTM D638, but widely used outside of the US.

What is ASTM D790?

ASTM D790 is a standard that specifies the test method for determining the flexural properties of unreinforced and reinforced plastics.

What is ASTM E8/E8M?

ASTM E8/E8M is a standard used to determine the tensile properties of metallic materials.

What is ISO 178?

ISO 178 is an international standard for determining the flexural properties of plastics.

What is ASTM D412?

ASTM D412 is a standard for measuring the tensile properties of rubber and elastomers.

What is ASTM C39?

ASTM C39 is a standard for testing the compressive strength of cylindrical concrete specimens.

What is ASTM F88?

ASTM F88 is a test standard that specifies the method for determining the seal strength of flexible barrier materials.